Ultra-precision Processing

TIME is a manufacturer specializing in “production goods,” which are the foundation for making high-quality IT equipment. We specialize in high-precision and high-precision processing of nonferrous metals, such as aluminum and stainless steel, and can also process titanium and heat-resistant alloys, which require advanced technology.

Example 1 Adsorption plate

The “adsorption plate” is used to adsorb semiconductor wafers. To enhance adsorption, it is important to have a flat surface. The suction plate manufactured by TIME has a flatness of 5 microns. The difference in surface height is only 5/1000 mm. Mirror finish is also available to make the surface smoother.

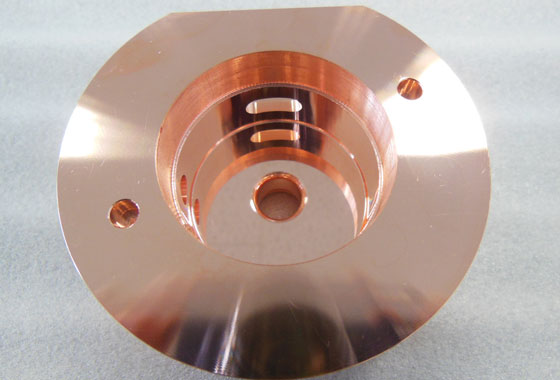

Example 2 Chamber

A “chamber” is a box with a vacuum inside. It is used in the manufacture of semiconductors. TIME’s strength is its ability to maintain a high vacuum.

Example 3 Large temperature control plate

Temperature control plates” are used to dry the RGB (red, green, and blue) pigments used in LCD screens. This equipment is indispensable for the manufacture of LCD screens. TIME manufactures large-size plates, which are difficult to manufacture. Thousands of pins are placed on the surface of the plate for efficient drying.