FSW (friction stir welding)

What is FSW (Friction Stir Welding)?

FSW” (Friction Stir Welding) is a technology that uses special tools to soften metal joints with frictional heat and knead them into one piece. FSW is usually used for rockets, aircraft, automobiles, railroads, etc., but TIME co.is utilizing it in the IT field.

Materials that can be joined

Many light metals such as aluminum alloys with relatively low softening temperatures can be joined. In addition to aluminum, we can also join aluminum alloys such as AZ31 and AZ61, titanium and its alloys, mild steel, zinc and lead. Our experience: aluminum and copper

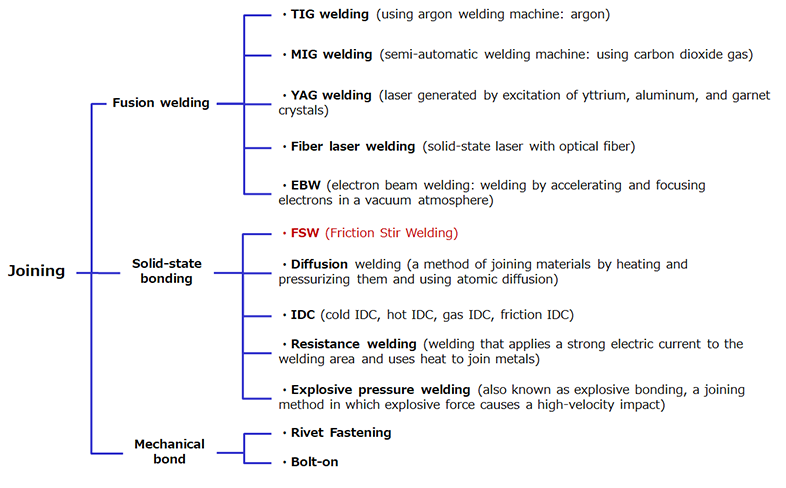

Joining Classification

5 Features of FSW Friction Stir Welding

- Leak-free joining.

- Free flow path (design with complex piping paths is possible).

- Integrated system from design to fabrication, including thermal analysis.

- When applied to temperature control plates, the volume occupied by conventional three-dimensional piping can be reduced to a space-saving two-dimensional integrated piping volume.

- 100% recyclable (no molten steel, solvents, or adhesives are used).