Particle Accelerator Production

What is an Accelerator?

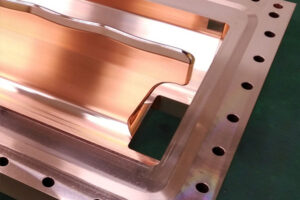

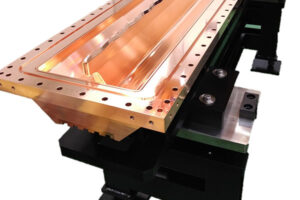

An “accelerator” incorporates Time’s proprietary technology. The accelerator is an “ultra-high vacuum” container with an extremely smooth interior, like a mirror, that maintains a vacuum state at the level of the universe.

This device, made of copper, incorporates all of TIME’s technology and requires very delicate, high-precision processing techniques. 2 types of accelerator, “RFQ” and “DTL,” have been patented.

The two types of accelerators, “RFQ” and “DTL,” are used for different purposes.

Accelerators are expected to be used in the medical and construction fields, and we are collaborating with various research facilities such as the Tokyo Institute of Technology and RIKEN to produce accelerators.

Applications of Accelerators

They are used for two applications in the medical field.

The first is sterilization of medical equipment and supplies. When accelerated electrons are applied to surgical scalpels, syringes, gowns, and other medical items, the accelerator exerts a sterilizing effect, thereby improving safety.

The second is cancer treatment. Accelerated electrons or heavy particles are irradiated to cancer cells to kill them. This is a type of radiation therapy and is performed as a highly advanced medical treatment.

In the construction field, it is used for non-destructive testing.

Non-destructive testing is a technique to examine the deterioration state of objects without destroying them. When neutrons are extracted and irradiated with accelerated ions, they reach deep into concrete and are absorbed by water, making it possible to examine internal cracks and flooding. Since this method is faster and more accurate than tapping, it is expected to be put to practical use in the inspection of bridges and tunnels.

Medical care and construction are fields closely related to people’s lives and livelihoods. TIME is contributing to safer and more affluent lifestyles for everyone with its technological and developmental capabilities, which have been refined independently.

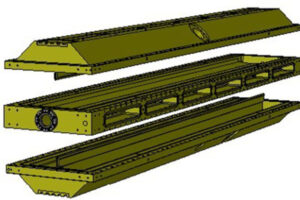

Three-Layer Structure RFQ

DTL

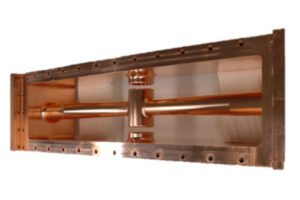

Buncher Cavity